Water treatment & Turbo expanders

(Turbo Expander)

Turboexpander Applications

- Hydrocarbon Gas / Oil Refinery Processing - LNG plant gas liquefication, , Fluid Catalyst Cracking (FCC), LPG recovery

- Cryogenic Air Separation - N2 gas production, cooling of air for stream condensation (Air Products, Praxair, Linde etc)

- Refrigeration - large scale gas refrigeration

- Energy Recovery - replaces expansion valves, electricity generation

- Geothermal Power Generation - power generation using ground water and refrigerants (134A or iso-butane)

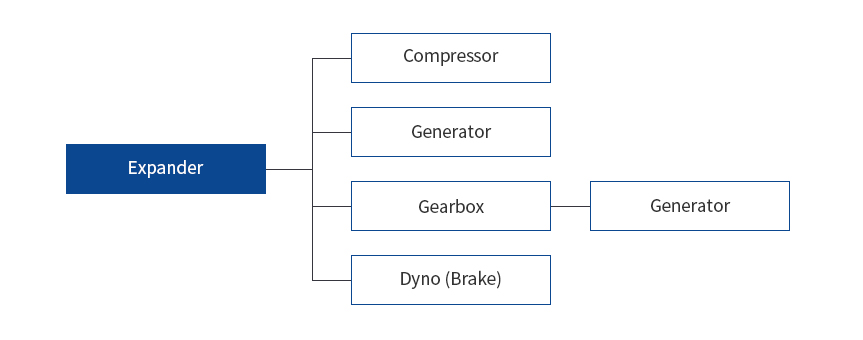

Turboexpander Types

- Four main types connected to the expander shaft

* You can view it by scrolling left and right.

| Turboexpander Configurations ⑴⑵ |

EC**/EG/ED | EC/EG/ED | EC/EG/ED | EC/EG | EC/EG | EC/EG | |

|---|---|---|---|---|---|---|---|

Frame Sizes |

L1000 | L2000 | L3000 | L4000 | L5000 | L6000 | |

Inlet Flow |

ACMH |

600 | 1,500 | 4,000 | 7,500 | 10,000 | 16,000 |

ACFM |

350 | 880 | 2,350 | 4,400 | 5,900 | 9,400 | |

Inlet Pressure |

BARG |

206 | 206 | 206 | 206 | 206 | 206 |

PSIG |

3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | |

Temperature |

Celsius |

-195 to 260 ℃ | -195 to 260 ℃ | -195 to 260 ℃ | -195 to 260 ℃ | -195 to 260 ℃ | -195 to 260 ℃ |

Fahrenheit |

-320 to 500 ℉ | -320 to 500 ℉ | -320 to 500 ℉ | -320 to 500 ℉ | -320 to 500 ℉ | -320 to 500 ℉ | |

RPM (max.) |

105,000*** | 52,000 | 31,000 | 29,000 | 18,000 | 15,000 | |

Seal Types |

Labryinth Seal | Labryinth Seal/ Dry Gas |

Labryinth Seal/ Dry Gas |

Labryinth Seal/ Dry Gas |

Labryinth Seal/ Dry Gas |

Labryinth Seal/ Dry Gas |

|

Wheel Power |

kW |

800 kW | 1,500 kW | 3,000 kW | 6,000 kW | 10,000 kW | 14,000 kW |

hp |

1,070 hp | 2,000 hp | 4,000 hp | 8,000 hp | 13,400 hp | 18,700 hp | |

| Bearing Types ⑶ | Oil | Oil/AMB | Oil/AMB | Oil/AMB | Oil/AMB | Oil/AMB | |